Advanced Tomato Production Line With Energy-saving Advantages

Product Details:

| Place of Origin: | Shanghai |

| Brand Name: | Gofun |

| Certification: | ISO, CE certification |

| Model Number: | GFM-TJL |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Aseptic bag |

| Delivery Time: | 90 days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 20 sets per year |

|

Detail Information |

|||

| End Product: | Tomato Paste, Tomato Sauce Or Ketchup, Tomato Juice, Etc | Final Product Brix: | 28%~30%, 36%~38% |

|---|---|---|---|

| Product Name: | SUS 304 / 316 Tomato Ketchup Production Machinery Mechanized Production | Fresh Fruit Input Capacity: | 500kg Per Hour ~ 25 Tons Per Hour |

| Capacity: | Customized | Product Category: | Tomato Processing Line |

| Usage: | Industrial Usage | Application: | Tomato |

| High Light: | Energy saving Advanced Tomato Production Line,Advanced Tomato Production Line |

||

Product Description

Product Description:

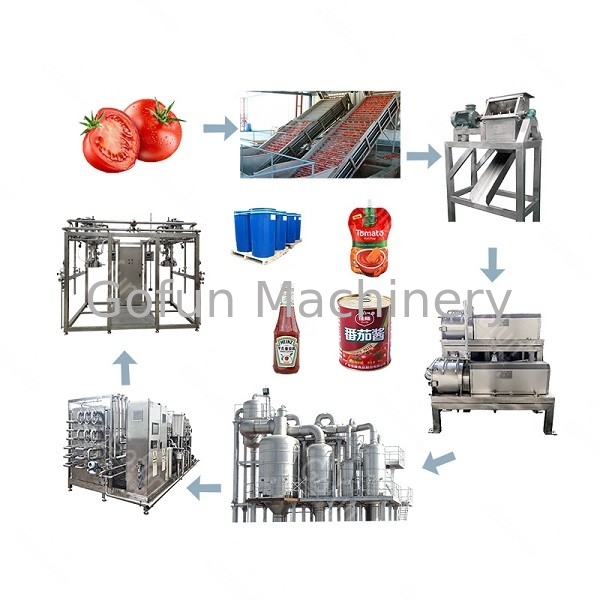

The tomato processing line features a tomato paste making machine and a tomato puree processing plant that can produce final products with Brix levels of 28%~30% and 36%~38%. The production line is designed to handle fresh, ripe tomatoes and can process them into high-quality tomato products with an extended shelf life.

The Tomato Sauce Manufacturing Line is equipped with advanced features, including a preheating system, pulping machine, refining machine, evaporator, sterilization equipment, and filling machine. The entire production process is fully automated, ensuring consistency and reliability in the production of the final product.

The Tomato Puree Processing Plant is designed to process fresh tomatoes into a puree that can be used for various applications. The production line can produce high-quality tomato puree with a Brix level of 28%~30%. The puree can be used as a base for various tomato products, including tomato sauce, ketchup, and tomato juice.

The Tomato Processing Line is highly efficient and energy-saving. The production line is designed to minimize water usage, making it an environmentally friendly solution. The advanced technology used in the production line ensures that the entire process is efficient and reliable.

The Tomato Processing Line is multifunctional, making it suitable for the production of various tomato-based products. The production line can produce tomato paste, tomato sauce or ketchup, tomato juice, and other tomato-based products. The production process is fully automated, ensuring that the final product is consistent and of high quality.

In conclusion, the Tomato Processing Line is a complete turnkey solution for the production of tomato-based products. It features advanced technology, making it highly efficient and energy-saving. The production line is multifunctional, making it suitable for the production of various tomato products, including tomato paste, tomato sauce or ketchup, tomato juice, and more.

Features:

- Product Name: Tomato Processing Line

- Final package: Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc

- Function: Multifunctional, tomato paste processing

- Voltage: 220V/380V

- Advantages: Energy-saving, high efficiency, water-saving

- Weight: Based on specific machines

Keywords: tomato paste production line, Tomato Production Line, tomatoes paste making machine automatic

Technical Parameters:

| Product Name | SUS 304 / 316 Tomato Ketchup Production Machinery Mechanized Production |

|---|---|

| Product Category | Tomato Processing Line |

| Function | Multifunctional, tomatoes paste making machine automatic, tomato processing machine automatic |

| End product | Tomato paste, tomato sauce or ketchup, tomato juice, etc |

| Final package | Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc |

| Dimension(l*w*h) | Adjustable |

| Fresh fruit input capacity | 500kg per hour ~ 25 tons per hour |

| Voltage | 220V/380V |

| Usage | Industrial Usage |

| Final product Brix | 28%~30%, 36%~38% |

Applications:

The Tomato Processing Line consists of several machines that work in tandem to provide an efficient and reliable tomato processing solution. The first machine in the line is the Tomato Sorting Machinery, which sorts and removes any unwanted materials from the tomatoes. The sorted tomatoes are then washed and conveyed to the next machine, the tomato paste making machine. This machine is responsible for crushing and grinding the tomatoes to produce tomato paste. The tomato paste is then heated in a continuous sterilization system, where it is sterilized and homogenized to achieve the desired consistency.

The Tomato Processing Line also includes a Tomato Juice Processing Facility, which is responsible for producing tomato juice from the remaining pulp and juice. The juice is then filtered and homogenized to produce a smooth and consistent product. The final product is then packaged in aseptic bags, which protect the product from contamination and spoilage.

The Tomato Processing Line can be used in various occasions and scenarios, including food processing plants, canned food factories, and beverage production facilities. It is suitable for processing large quantities of tomatoes and is highly efficient, with a power consumption of 10kw. The dimension of the product is adjustable and the weight is based on specific machines. The product is available at a negotiable price with a minimum order quantity of 1 set. The payment terms include T/T, L/C, and Western Union, and the supply ability is 20 sets per year. The delivery time is 90 days, and the packaging details include aseptic bags.

Support and Services:

The Tomato Processing Line product technical support and services include:

- Installation and commissioning of the processing line.

- Training for operating and maintaining the equipment.

- Regular maintenance and repair services.

- Supply of spare parts and components.

- Technical assistance and troubleshooting support.

- Upgrades and retrofits for existing equipment.

Our team of experienced technicians and engineers are dedicated to providing prompt and effective support to ensure your processing line operates at peak performance and efficiency.

Packing and Shipping:

Product Packaging:

- All products will be securely packed in sturdy boxes to prevent damage during shipping.

- Each component of the Tomato Processing Line will be individually wrapped and cushioned with bubble wrap or foam to ensure safe transportation.

- The boxes will be labeled clearly with the product name and any handling instructions.

Shipping:

- We offer worldwide shipping via reliable carriers such as DHL, FedEx, and UPS.

- Shipping costs will vary depending on the destination and weight of the package.

- Customers will receive a tracking number once their order has shipped, allowing them to monitor the delivery status.

- Please allow 3-5 business days for processing and handling of orders before shipment.

FAQ:

Q: What is the brand name of this tomato processing line?

A: The brand name of this tomato processing line is Gofun.

Q: What is the model number of this tomato processing line?

A: The model number of this tomato processing line is GFM-TJL.

Q: Is this tomato processing line certified?

A: Yes, this tomato processing line is certified with ISO and CE certification.

Q: Where is this tomato processing line made?

A: This tomato processing line is made in Shanghai, China.

Q: What is the minimum order quantity for this tomato processing line?

A: The minimum order quantity for this tomato processing line is 1 set.

Q: Is the price negotiable for this tomato processing line?

A: Yes, the price is negotiable for this tomato processing line.

Q: What are the payment terms for this tomato processing line?

A: The payment terms for this tomato processing line are T/T, L/C, and Western Union.

Q: What is the supply ability for this tomato processing line?

A: The supply ability for this tomato processing line is 20 sets per year.

Q: What is the delivery time for this tomato processing line?

A: The delivery time for this tomato processing line is 90 days.

Q: What are the packaging details for this tomato processing line?

A: The packaging details for this tomato processing line are aseptic bag.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()